|

|

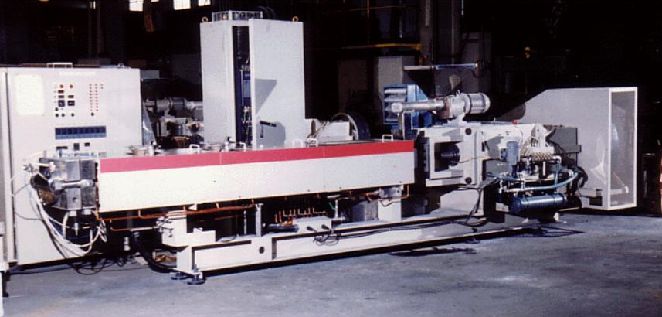

| 1 | : | High Quality with Excellent Performance |

| 2 | : | Versatility with Easy Handling |

| 3 | : | Sleek design for Long Lasting Life |

| 4 | : | Bench mark designing for middle range |

| 5 | : | Sturdy and simple for consistent operation |

| 6 | : | Step up model with production capacity 500kg/hr ~ 1,500kg/hr |

| 7 | : | Featuring Industrial beauty as Japan-make |

| 8 | : | High Reliability |

| 9 | : | Best Selling model in 50 years |

| 10 | : | Best fitted to High volume of master batch Compounding, profiling, film and fiber production. |

| 1 | Type | Co-rotated twin screw extruder (IncludingTwin Screw Feeder) |

| 2 | Capacity | 500kg/hr(ABS pellet) (90kw main motor)(Standard) |

| 1,500kg/hr(ABS Pellet)(300kw main motor)(Option) | ||

| 3 | Dimension | 800mm(CH), 5,500mm(L), 2,300mm(W), 1,600mm(H), |

| 4 | Weight | 7.0 ton |

| 5 | Voltage and capacity of power supply |

| Voltage | 380 ~ 440V, 50 / 60Hz, 3 phase(Standard) | |

| Capacity | 160KVA by AC 90kw main motor (Standard) | |

| 370KVA by AC 300kw main motor (Option) | ||

| 6 | Barrel | Nitrided steel with Hardness over HRC63 (Standard) |

| Anti-Abrasion barrel with Hardness SKD 61(Option) | ||

| L/D 40(Standard) | ||

| L/D36(Option), L/D44(Option), L/D48 (Option), Other(Option) | ||

| 7 | Screw | Segment type with Involute Spline Shaft made of Hardened SKD |

| 8 | Heater | Brass Casted Heater nine blocks |

| 9 | Temperature Control |

| 9 Zone | ||

| 10 | RPM | 50 ~ 440 rpm(Main motor 90kw) (Standard) |

| 50 ~ 550 rpm(Main motor 300kw) (Option) | ||

| 11 | Main Motor | 90kw (Standard) |

| 132kw(Option), 160kw(Option),200kw(Option), 300kw(Option) | ||

| AC Motor Controlled by Inverter | ||

| 12 | Other Options | Safety Clutch(Option), Resin Thermometer(Option), Resin Pressure Sensor(Option) |

| Side Feeder(Option), Screen Changer(Option), Vacuum Pump(Option) etc. |